Mehler Protection Introduces Omega Core, a Next-Generation Ultra-Light Combat Helmet

FULDA, GERMANY (06.02.2026)

Mehler Protection, part of the Mehler Systems and a leading provider of personal and platform ballistic protection solutions, is expanding its helmet portfolio with Omega Core, a next-generation ultra-light combat helmet designed for modern tactical and military mission profiles.

Omega Core combines an optimised UHMWPE composite core with a shell-integrated energy-dissipation system and an ergonomically engineered interior. The result is an outstanding weight-to-performance ratio that enhances mobility while helping reduce operational fatigue and neck strain during extended missions.

The new helmet system will be showcased at Enforce Tac 2026 as part of Mehler Protection’s current helmet portfolio.

Engineered for Mobility, Integration, and Operational Flexibility

Omega Core features a sophisticated ballistic construction paired with an open rail architecture and modular interfaces for NVG mounts, visors, communications systems, hearing protection, and additional mission accessories.

Inside, multi-chamber pads and adaptive anchoring points minimise micro-movements under dynamic loads, improving stability, comfort, and overall fit. A continuously ventilated suspension net helps reduce heat build-up and perspiration during high-intensity activity.

The shell concept is engineered for low backface deformation and optimised fragment deflection. Thanks to its modular platform architecture, Omega Core can be configured for a wide range of operational scenarios, from highly mobile operations to environments with variable threat levels.

Setting a New Benchmark in Ultra-Light Helmet Systems

“With Omega Core, we are setting the benchmark for ultra-light, fully integrable combat helmets. The system is Made in Germany and underpinned by a resilient European supply chain. Operators benefit from around 20 percent weight savings compared to the current Bundeswehr combat helmet, without compromising protection, ergonomics, or system integration,” says Dr. Mario Amschlinger, CEO of Mehler Systems.

Omega Core ranks among the lightest helmet systems in its class and delivers clear advantages in mobility and reduced fatigue during prolonged missions.

Tested to Military-Relevant Standards

Omega Core is tested against the “Ballistic Helmet” standard (Chapter 3.2, May 2010), the STANAG 2920 V50 fragmentation protection procedure, and the NIJ STD 0106.01 standard.

Ballistic testing with operationally relevant handgun ammunition, including 9 mm FMJ RN, .357 SIG FMJ FN, and .44 Mag SJHP, is conducted to evaluate performance. These procedures ensure ballistic resistance, impact attenuation, and material durability meet military user requirements.

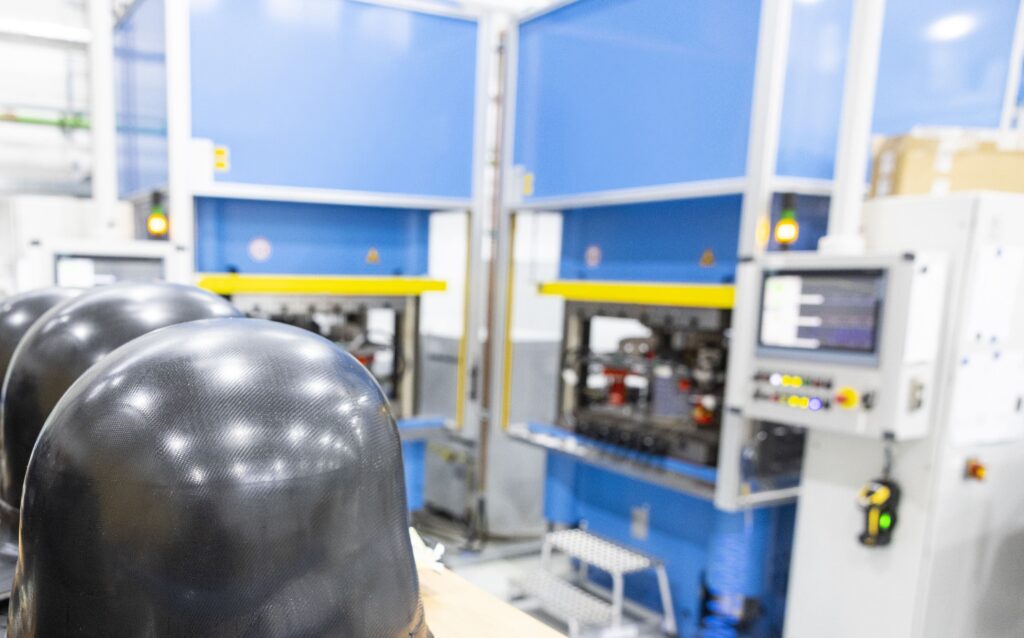

Scalable Production in Germany

Series production takes place at Mehler Protection’s dedicated facility in Fulda, Germany. The automated production line provides capacity for more than 50,000 helmets per year and can be scaled to three times this volume at short notice.

The production strategy is based on rapid scalability, dual sourcing of critical components, and qualified supplier networks across Europe, ensuring reliable delivery for large-scale armed forces programmes.

Discover Mehler Protection’s full helmet portfolio.