Harnessing 3D Printing for Enhanced Ballistic Solutions

KÖNIGSLUTTER, GERMANY (17.10.2024)

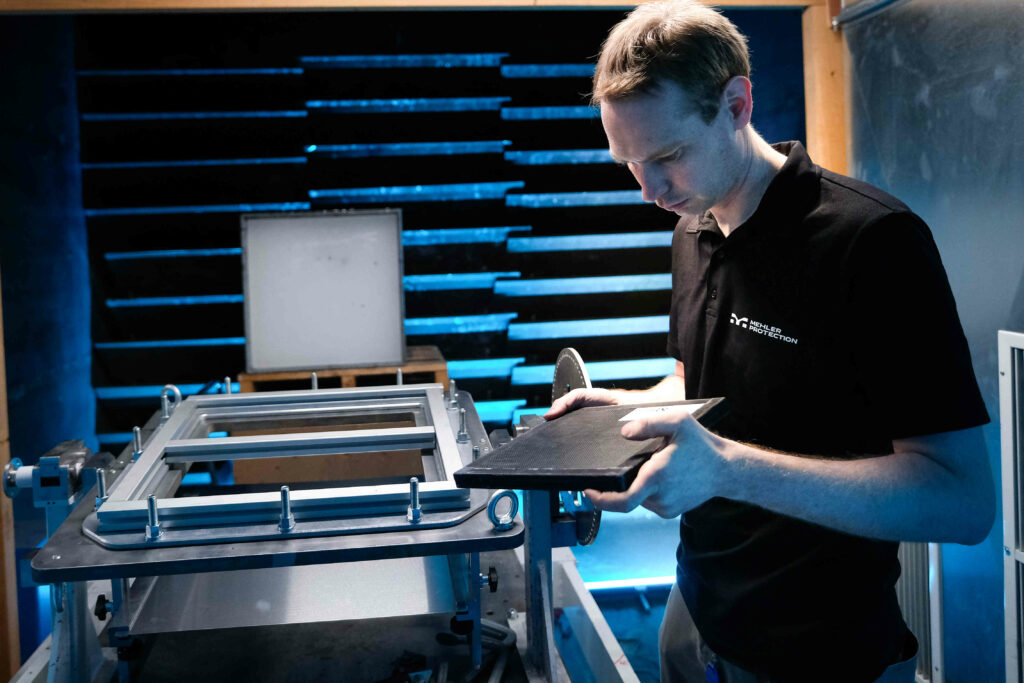

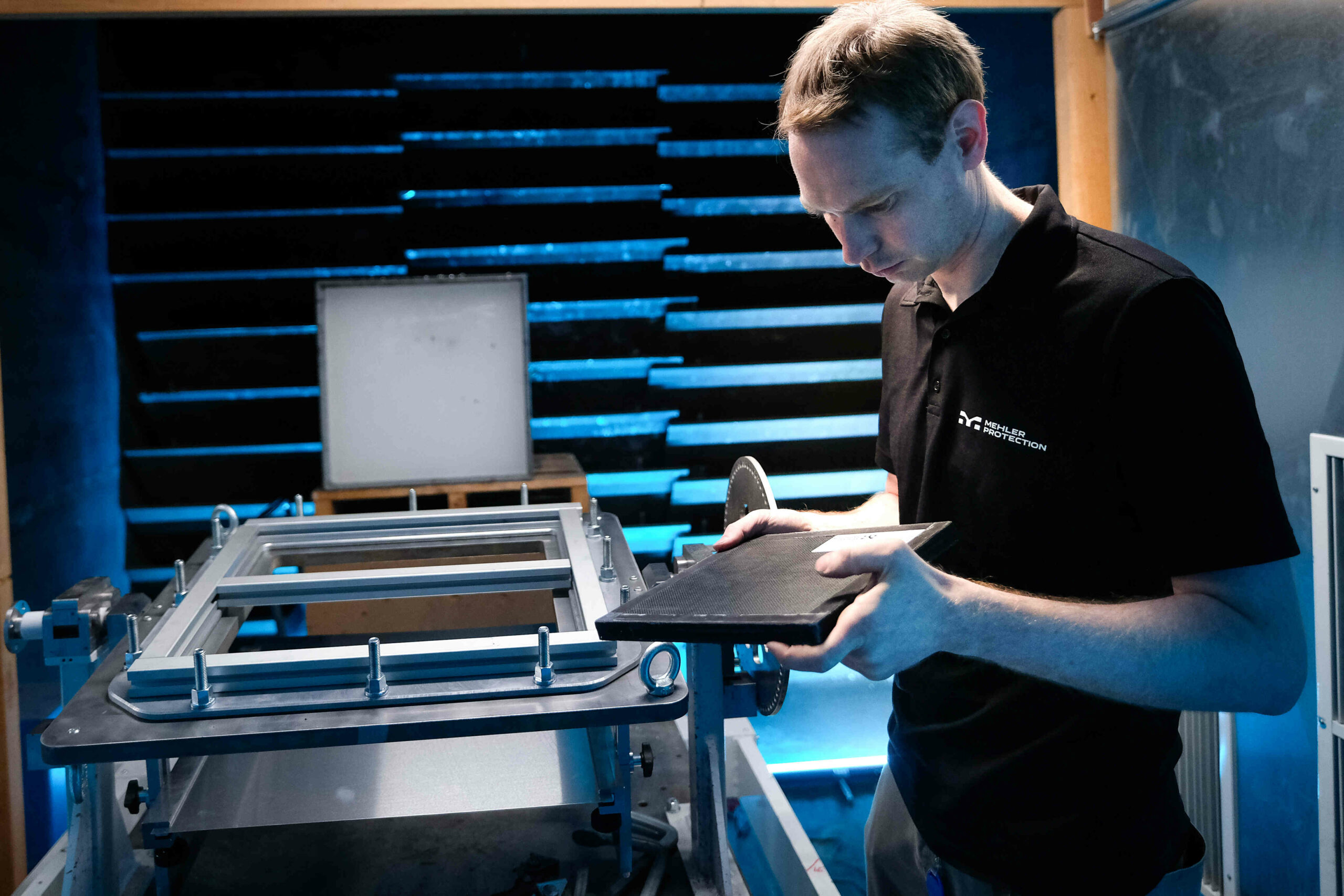

Mehler Protection is elevating ballistic protection solutions with the introduction of PROTEC3D, a product line that employs 3D printing technology to increase design flexibility, reduce weight, and create complex components.

Innovation in Design and Manufacturing

3D printing, or additive manufacturing, is transforming the production of ballistic protection solutions. This technology offers significant design flexibility, enabling the creation of complex structures that traditional manufacturing methods may not accommodate.

By utilising a Selective Laser Melting (SLM) process, Mehler Protection can produce customised components that ensure consistent ballistic resistance.

Additionally, the option for cathodic dip coating (CDC) enhances corrosion protection without affecting the material’s ballistic properties, which is often a challenge with conventional armour steel.

Efficiency and Functional Integration

A key advantage of 3D printing technology is its capacity to manufacture complex components in a single step, resulting in weight reduction and enhanced structural integrity.

This process enables the direct integration of additional features, such as cooling channels and mounting points, thereby improving the reliability and lifespan of the protection solutions.

Speed and Cost Advantages

3D printing technology significantly reduces lead times and lowers production costs. While traditional manufacturing processes often require lengthy production times for moulds and tools, 3D printing can produce prototypes and small batches in just a few days.

Additionally, the efficient use of materials in additive manufacturing leads to further cost savings, making it ideal for time-sensitive applications.

Diverse Applications and Future Potential

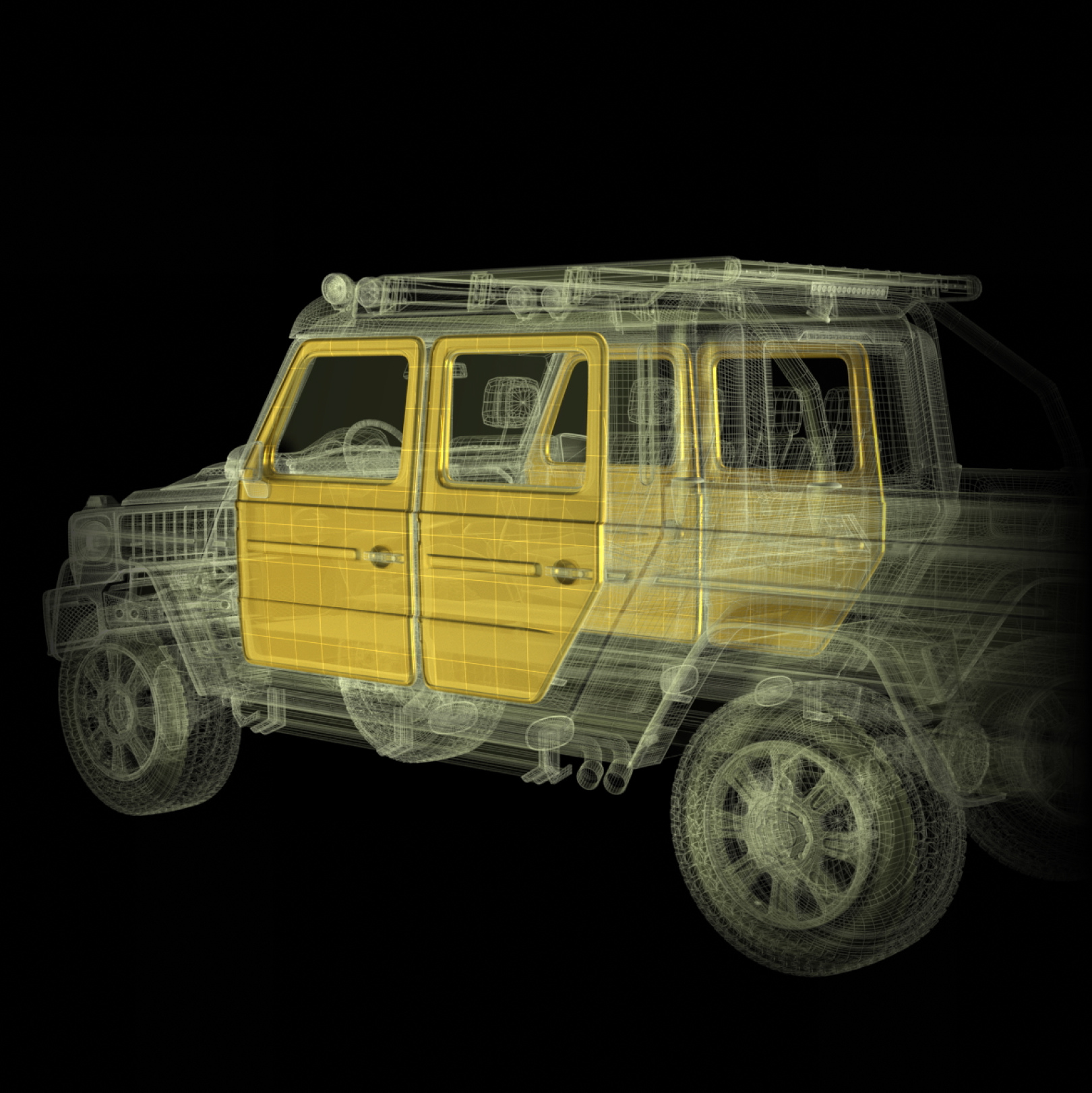

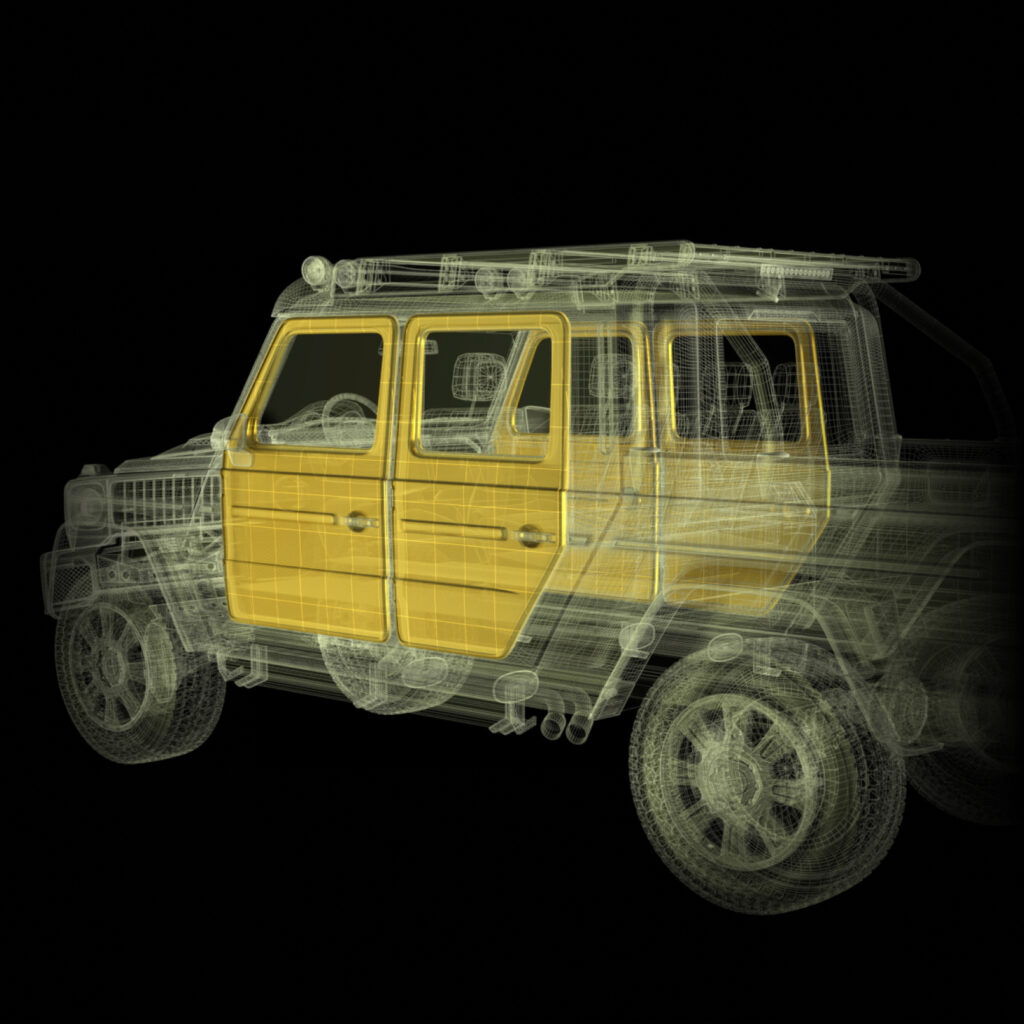

Mehler Protection is leveraging 3D printing technology to develop innovative ballistic protection solutions that meet STANAG 4569 standards. This approach complements the existing M-RACC (Multirole Armour Composite Components) product line, which traditionally utilises armour for modular, passive defence against various threats, including ballistic projectiles, shaped charges, IEDs, and mines.

The integration of 3D printing into these solutions enhances design flexibility and performance, making them suitable for use in military vehicles, ships, helicopters, and critical infrastructure.

The PROTEC3D line is already demonstrating its potential in civil protection vehicles, achieving significant weight reductions in protective window frames. At Eurosatory 2024 in Paris, Mehler Protection showcased a PROTEC3D sensor housing that not only meets STANAG Level 3 requirements but also incorporates cleaning and cooling features.

This innovative technology was also developed for military land vehicles, addressing vulnerabilities at common weak points by utilising ballistic-protected media disconnectors and cable feed-throughs.

Mehler Protection is actively expanding the application of PROTEC3D across various environments, including land, sea, air, and critical infrastructure.

Discover the Possibilities of PROTEC3D

As Mehler Protection continues to refine and adapt PROTEC3D for specific needs, it presents opportunities for enhanced design flexibility, ballistic performance, and efficient production, positioning the company to advance ballistic protection solutions.

For more details on Mehler Protection’s latest advancements, visit the company’s website.